Today’s blog title refers to the fact that I just fully revamped all of my string sets at Harp Guitar Music, both steel and nylon. And, man, is my brain fried!

It took 8 years for someone (DR Strings) to take harp guitars seriously, and it’s taken even more than that for anyone to figure out (well, make it practical) to do realistic tension measurements on any of these strings. We’ve been mostly guessimating with the old formula that D’Addario once made for just their phosphor bronze neck strings, which doesn’t help us at all with nylons, and is less than ideal with other brands or thicker double-wound strings.

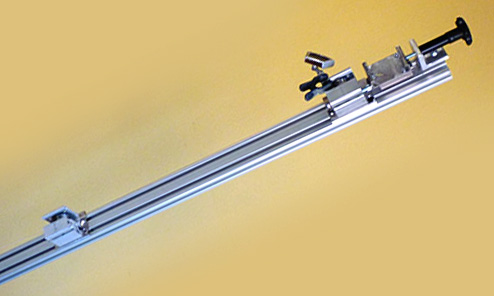

So last year I finally tried building my own low budget string tension measuring machine, but after wasting a couple hundred dollars and way too many man hours, my crude contraption simply wasn’t remotely repeatable.

Enter recent harp guitar convert, Steve Silva (above). An old friend of Frank Doucette’s and excellent guitarist, he’s been at a couple Harp Guitar Gatherings now and recently took delivery of a brand new Pellerin harp guitar. He’s also Director of Product Engineering at Tecnau, and utilizing his expertise and some expensive machinery and gauges, he recently constructed a truly state-of-the-art string tension machine (just for the Pellerin and his own amusement!). After encouraging initial tests, he further hand-machined clever bits of apparatus in order to make the test mostly non-destructive (so the strings are pretty much “like new” after testing).

I immediately sent him a sample of pretty much my entire stock of harp guitar strings and he went to town on ‘em. I’ve spent a few weeks crunching the data and just finished completely re-doing all of my Harp Guitar Music sets. We’ve finally got this down to a science! It’s not quite perfect math, as I’m still limited to available strings (and with custom strings, a practical chosen selection – I’m not about to order every single thousandth increment!), but close enough.

I immediately sent him a sample of pretty much my entire stock of harp guitar strings and he went to town on ‘em. I’ve spent a few weeks crunching the data and just finished completely re-doing all of my Harp Guitar Music sets. We’ve finally got this down to a science! It’s not quite perfect math, as I’m still limited to available strings (and with custom strings, a practical chosen selection – I’m not about to order every single thousandth increment!), but close enough.

Test results from Steve’s system were amazingly reliable. Taking multiple tension readings at various pitches and lengths yielded under ±1% variance for steel strings and ±2% for nylon (which Steve learned require a “stretching period”).

All that’s left to do is try to get a few more custom gauges from LaBella, as the John Doan set is far too limiting (as I’d known, but the results are even more telling). Other results, some expected, some frustrating, include:

- There are differences in tension between equivalent gauges of different brands, and differences aren’t uniform (in percentage or direction) across the range of gauges.

- All string types and brands were found to have random non-linearity across their range; i.e: string tension may or may not change proportionately with string thickness increments as one would expect (and desire).

- String manufacturers may not precisely duplicate the exact materials for subsequent orders of custom strings. I only checked a couple, and all were in the noise, except one at 4% decrease in tension (not a deal breaker as far as I can see, but something to watch for).

- Results when plugging in different pitches or lengths in the “active formula” chart were interesting and occasionally counter-intuitive. But the numbers don’t lie!

I can now more accurately and quickly calculate most any set of harp guitar sub-basses – steel and nylon, at any pitch and length. I’ve added a service for this on the site, as it’s asked of me a lot, and, frankly, I know that a lot of players are buying my available sets for convenience (thanks!), but without always being aware of how far their instruments may deviate from the string scale lengths my sub-bass sets are designed for (e.g: for steel, a median of a selection of vintage Dyers).

Please check out all the tweaked sets and information for either steel or nylon sub-bass strings. International customers please don’t forget to first note your specific Ordering instructions page.

OK, so all this new detail is great, right? But this painstaking “sub-bass redux” is really just meant to be a controlled starting point, while providing some useful knowledge of total tension applied to your instrument. Much more important are one’s personal reaction to string gauges, which ultimately comes down to tone and feel.

While I can standardize and control what I label “light” or “medium” tension across all these new string sets, that’s only a reference point. What you call light and medium or extra-light or heavy may be vastly different.

Why? Playing style, musical goals and personal taste (along with differences in instruments).

For example, I’m amazed that Andy Wahlberg – who comes across as thumping those basses – is somehow getting away with what I call an “extra-light” (nearly “XXL”) for his low F (a D’Addario .070). It never buzzes or boings, and he’s not playing as hard as it looks or sounds.

Conversely, customer Steve Sjuggerud mentioned the other day that he found my Medium SB tuning set (the heaviest one I offered) perfect except for the low G which was too light for him. This is due to a simple harp guitar performance technique many of us are well familiar with: since the low, outside string is one we don’t have to worry about missing or looking at, we tend to get carried away in our harp guitar exuberance and slam it!

As you know, I’ve seen hundreds of harp guitars and nearly as many players and no two play quite the same way. And each has their own taste in sub-bass tension. Interestingly though, most players seem able to adapt to a wide variety of tensions without even being aware of it. But those who are acutely aware may still differ. For example, the Powell brothers prefer to err on the side of caution and string their sturdily-built Tonedevils with ~22 lbs per string (what I sell as “Extra Light”), and get good sound out of them – while I string my priceless, lightly-built vintage Dyer with ~28 per (my “Medium”). Go figure.

At least with these new accurate calculations we can now call the art of harp guitar sub-bass stringing controlled chaos!

Hello Gregg. Great news and just what I needed!

Will send measures and fee soon. Sean.

This very useful for Harp Guitar Luthiers! Thanks Gregg/Steve.

Michael

I’m very impressed with Steve’s tension device and Gregg’s application of the results. I imagine it will prove very beneficial for those who want to fine tune the strings they use. Nice nice job.